DURHAM – University engineers Duke have demonstrated a dual-mode heating and cooling device for building climate control that, if widely deployed in the US, could reduce HVAC energy use by nearly 20 percent.

The invention uses a combination of mechanics and materials science to harness or eject certain wavelengths of light. Depending on conditions, rollers move a sheet back and forth to expose heat-trapping materials in one half or cooling materials in the other. Specially designed at the nanoscale, one material absorbs energy from the sun and traps existing heat, while the other reflects light and allows heat to escape through the Earth's atmosphere into space.

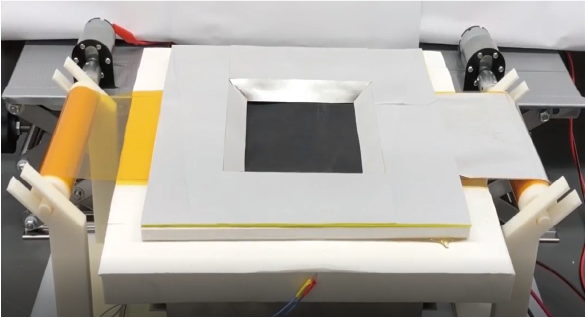

Dual mode heating and cooling device test system for solar building climate control. (Duke University photo)

"I think we are the first to demonstrate a reversible thermal contact, which allows us to switch between the two modes of heating or cooling," said Po-Chun Hsu, assistant professor of mechanical engineering and materials science at Duke and team leader. “This allows the material to be movable while maintaining good thermal contact with the building so that heat can enter or let out”.

The results appeared online November 30, in the journal Nature Communications.

About 15% of energy consumption in the US, and more than 30% globally, goes to heating and cooling buildings, which is responsible for about 10% of global greenhouse gas emissions. greenhouse. However, until now, most approaches to minimizing the carbon footprint have only addressed heating or cooling. That leaves temperate areas of the world that require both heating and cooling throughout the year, or sometimes just 24 hours, in the cold. In the new article, Hsu and his team demonstrate a device that could potentially keep us comfortable or cool as the weather changes.

Po-Chun Hus

Po-Chun HusThe specially designed blade begins with a polymer compound as a base that can be expanded or contract when electricity is passed through it. This allows the device to maintain contact with the building to transmit energy and, at the same time, it can be disengaged so that the rollers can switch between modes.

The part of Blade cooling has an ultra-thin silver film covered by an even thinner layer of transparent silicone, which together reflect the sun's rays like a mirror. The unique properties of these materials also convert and emit energy into mid-range infrared light, It does not interact with gases in the Earth's atmosphere and easily passes into outer space.

When a change in climate brings the need for heating, the electrical charge is released and the illos pull the blade down a track. This changes the cooling and reflective half of the sheet to the heat absorbing half.

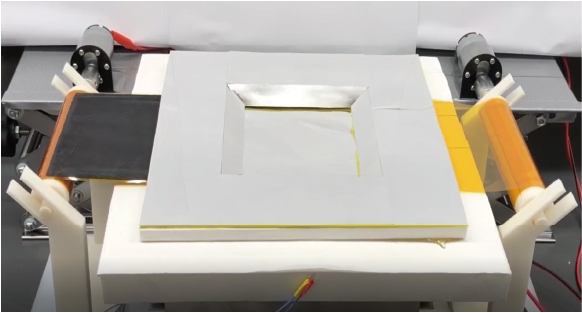

Dual device in heating mode that shows a square of material that absorbs solar energy and transmits it to the building's HVAC system.

Dual device in heating mode that shows a square of material that absorbs solar energy and transmits it to the building's HVAC system.To heat the building below, the engineers used an ultra-thin layer of copper topped by a layer of zinc-copper nanoparticles. By making the nanoparticles to a specific size and separating them at a certain distance, they interact with the copper beneath them in a way that traps light on their surface, allowing the material to absorb more than 93% of the heat from sunlight.

Hsu and his team see the device as something that could work with existing HVAC systems, rather than a complete replacement.

“Instead of directly heating and cooling the building, we could use a water panel to bring hot or cold water to a heat pump or system boiler ”Hus said. "I also imagine that with additional engineering, this could also be used on walls, forming a kind of interchangeable building envelope." Hsu said.

Dual device in cooling mode that shows a square of material that reflects solar energy in outer space and achieves cooling

Dual device in cooling mode that shows a square of material that reflects solar energy in outer space and achieves coolingMoving forward, the team is working on various aspects of the design to move from a prototype to a scalable one for manufacturing. Among these, Hsu explained, are concerns about long-term wear and tear of moving parts and specialized material costs. For example, they will investigate whether lower-cost aluminum can substitute for silver and are also working on a static version that can change modes chemically rather than mechanically.

Despite the many obstacles, Hsu believes that this technology could be a boon for energy savings in the future. And he is not alone.

"We are already working with a company to stop Determine the ideal locations to implement this technology, "Hsu said. "And because almost all climate zones in the United States require heating and cooling at some point in the year, the benefits of a dual-mode device like this are obvious."

(C) Duke University

Be First to Comment